je@jeeyvee.com

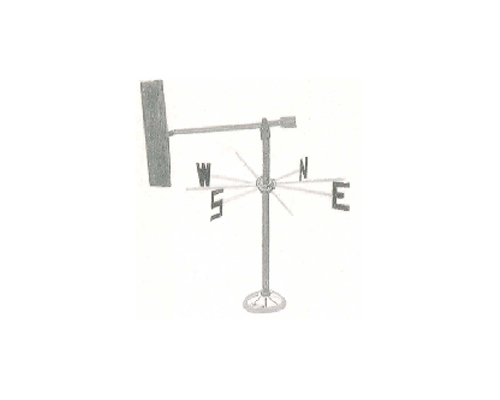

The aluminum material is used for the fabrication of the instrument so it may withstand permanent exposure in the open and has a long life. The fin is securely fixed to the horizontal arm a~ one end and on the other did of the arm counter weight is fixed in such a way that the complete assembly is accurately balanced about the spindle. The horizontal arm is perfectly straight and the top end of the spindle projecting up from the horizontal arm is held firmly by a nut. The bearing housing cap is locked to the spindle by a steel pin.

The spindle is a straight rod turned and finished accurately such that it revolves in the bearings with the minimum friction. The spindle is locked to the bearing by means of a steel pin. The mounting ring for direction arms is made of aluminum metal and carry the eight cardinal and inter-cardinal direction arms. It is fixed to the top of the main support tube by screws. The mounting ring has rest level over a collar at the top of the main support is a straight galvanized steel pipe with standard pipe threads at one end for screwing into the base. The other end takes the collar and mounting ring for direction arms. The main support tube is locked to the base by a suitable steel pin. The base is cast from aluminum material and has three holes for taking the foundation bolts. The external surface is suitably protected with primer and finishing paint. The four directions letters N, E, Sand W is painted with red color. The complete instrument is packed by dismantled the fin from the horizontal arm and the direction rods from the mounting ring in a strong wooden case to withstand all possible transit risks.